Case Study

Posted on

Every year cement and concrete production generate around 8% of global emissions, making cement production the world's single biggest industrial cause of carbon pollution.

Concrete is the most widely used construction material in the world, but its production is a major source of carbon emissions, primarily due to the use of Portland cement.

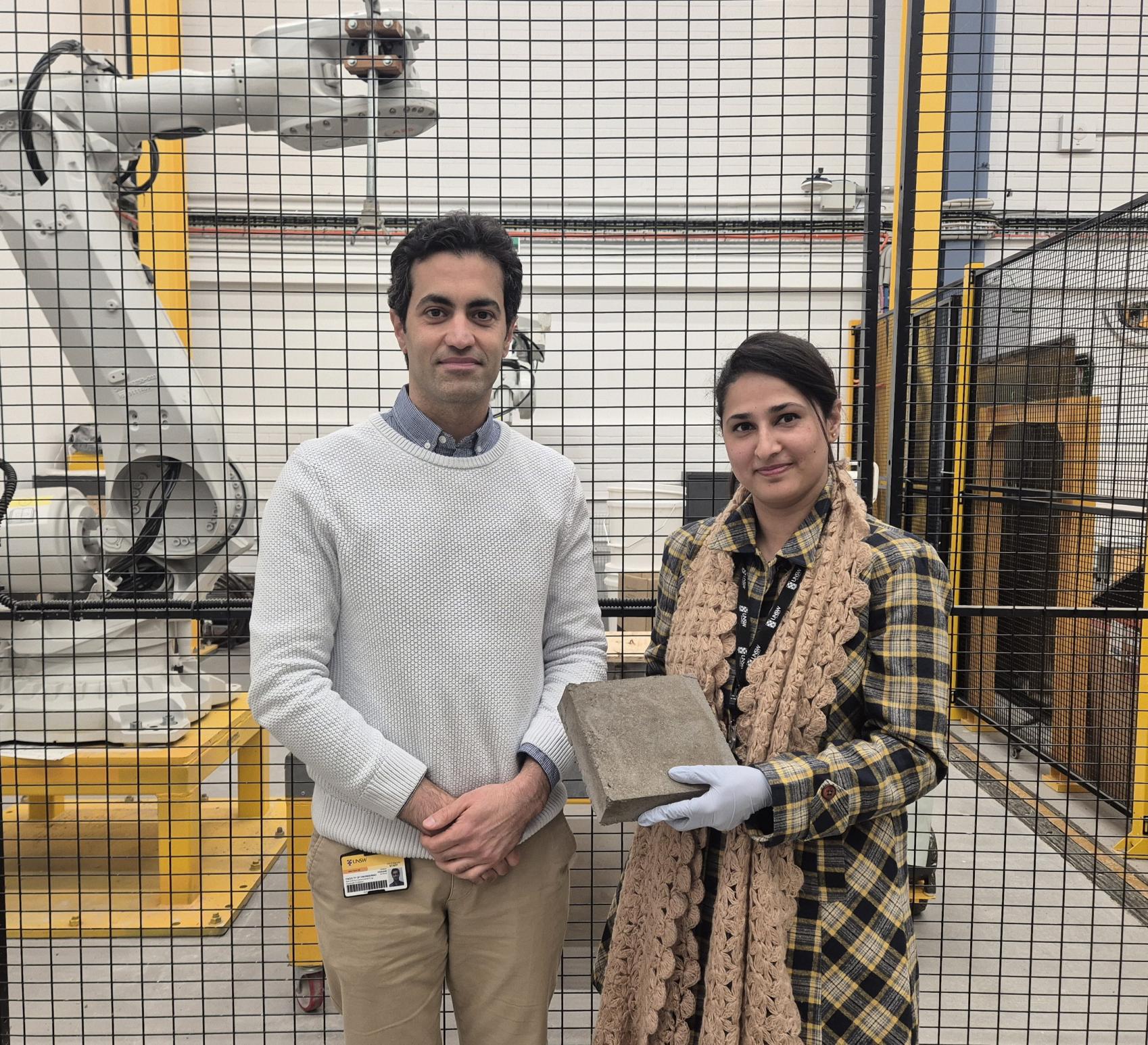

Dr Ali Kashani and Dr Zunaira Naseem, in collaboration with industry partners Adbri and Australian Steel Mill Services (ASMS), are developing a low-emission carbon dioxide recycling technology that promises to transform concrete masonry production.

This collaboration is one of nearly a hundred projects supported through the AEA Seed grants which are advancing research commercialisation in priority areas including renewables and low emission technologies.

As the country transitions towards our net zero future, this pioneering project at University of New South Wales Sydney is leading the charge toward a more sustainable future in construction.

In a groundbreaking development, Dr. Kashani and Dr. Naseem have successfully created a low-carbon concrete mix that replaces 50% of Portland cement with steel slag—a by-product of steel manufacturing. This innovative approach not only reduces the carbon footprint of concrete but also significantly enhances its strength and durability.

The potential impact of this project on the construction industry is immense. By replacing traditional Portland cement with a low-carbon alternative and utilising CO2 in the production process, this technology not only reduces carbon emissions but also repurposes industrial waste. The result is a sustainable building material that supports Australia’s net-zero carbon goals and sets a new standard for eco-friendly construction.

The project’s Lead Entrepreneur Dr. Ali Kashani said that the AEA Seed funding has been pivotal in enabling the development of innovative low-carbon concrete technologies.

"Through this project, we're not only cutting down on carbon emissions but also transforming industrial waste into valuable construction materials, paving the way for a sustainable future," Dr Kashani said.

The partnership with Adbri and ASMS has been critical in translating our research into practical, commercial applications that can have a real impact on reducing carbon footprints in the building sector.”

Australia’s largest masonry producer Adbri and ASMS, the main supplier of steel slag in the country, have provided critical insights into the commercial viability and supply chain logistics of the low-carbon masonry units. This partnership has accelerated the development process and ensured that the solutions being developed are aligned with industry standards and market needs.

In the first project milestone, the team developed a concrete masonry unit (pictured) with early compressive strength up to 140% higher than the standard control mix. Remarkably, this was achieved while reducing the embodied carbon of the concrete by 75%. A critical factor in these achievements has been the successful implementation of CO2 utilisation technology, which captures and recycles carbon dioxide into the concrete, turning a waste product into a valuable resource.

The team is currently working to refine the concrete mix and CO2 utilisation parameters to achieve an ultra-low carbon footprint without compromising on quality. This phase is focused on developing a high-quality, cost-effective prototype for commercialisation. The team is also conducting a comprehensive cost and supply chain analysis in collaboration with industry partners to ensure the product is both commercially viable and scalable.

AEA is a $1.6 billion Australian Government investment aimed at transforming Australia’s research translation and commercialisation landscape.

The program is funding projects that align with national priorities to help take innovative ideas through to proof-of-concept and proof-of-scale as projects progress towards commercialisation and the creation of new businesses.

Find out more about and follow the AEA LinkedIn page for updates.