Case Study

Posted on

Recent rapid advances in solar technology have seen millions of Australian households install panels on their roofs to reap the benefits of cheap and renewable energy. What does the next decade hold for solar energy innovation?

In the 10 years leading up to 2020, the cost for large scale solar panel dropped by more than 80 per cent. The technology has been adopted eagerly in both commercial and residential settings, making up an increasing amount of energy supply in Australia.

With current silicon solar cell technology approaching its efficiency limit, researchers are working on new technology called tandem solar cells, which can generate more energy by stacking other light absorber layers on a single silicon panel.

Tandem solar cells use a different material in addition to the standard silicon (Si) to more efficiently convert the solar spectrum and thus produce more energy per cell.

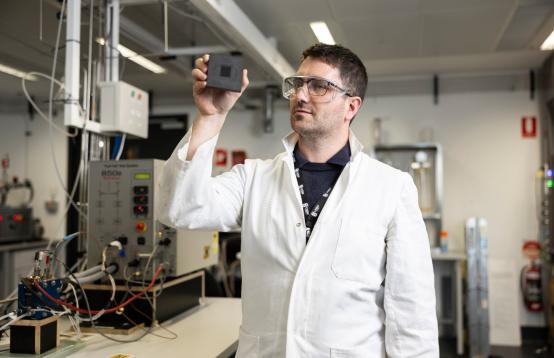

Funded by an AEA Seed grant, Dr Ziheng Liu and the tandem solar cell team at the University of New South Wales are developing a large-scale production method for the next generation of silicon solar cells.

“Tandem solar cell technology is an exciting development but there’s a need for more research to address the question of how we can manufacture the cells at a large scale,” Dr Liu said.

“By securing funding through the AEA Seed program, we were able to demonstrate the real-world potential of the novel polymer technology that we are developing.”

As with any new technology, research and development is required to turn the theoretical into real-world applications. The compatibility between the top cell and Si bottom cell raises a limit for the large-scale manufacturing of tandem solar cells.

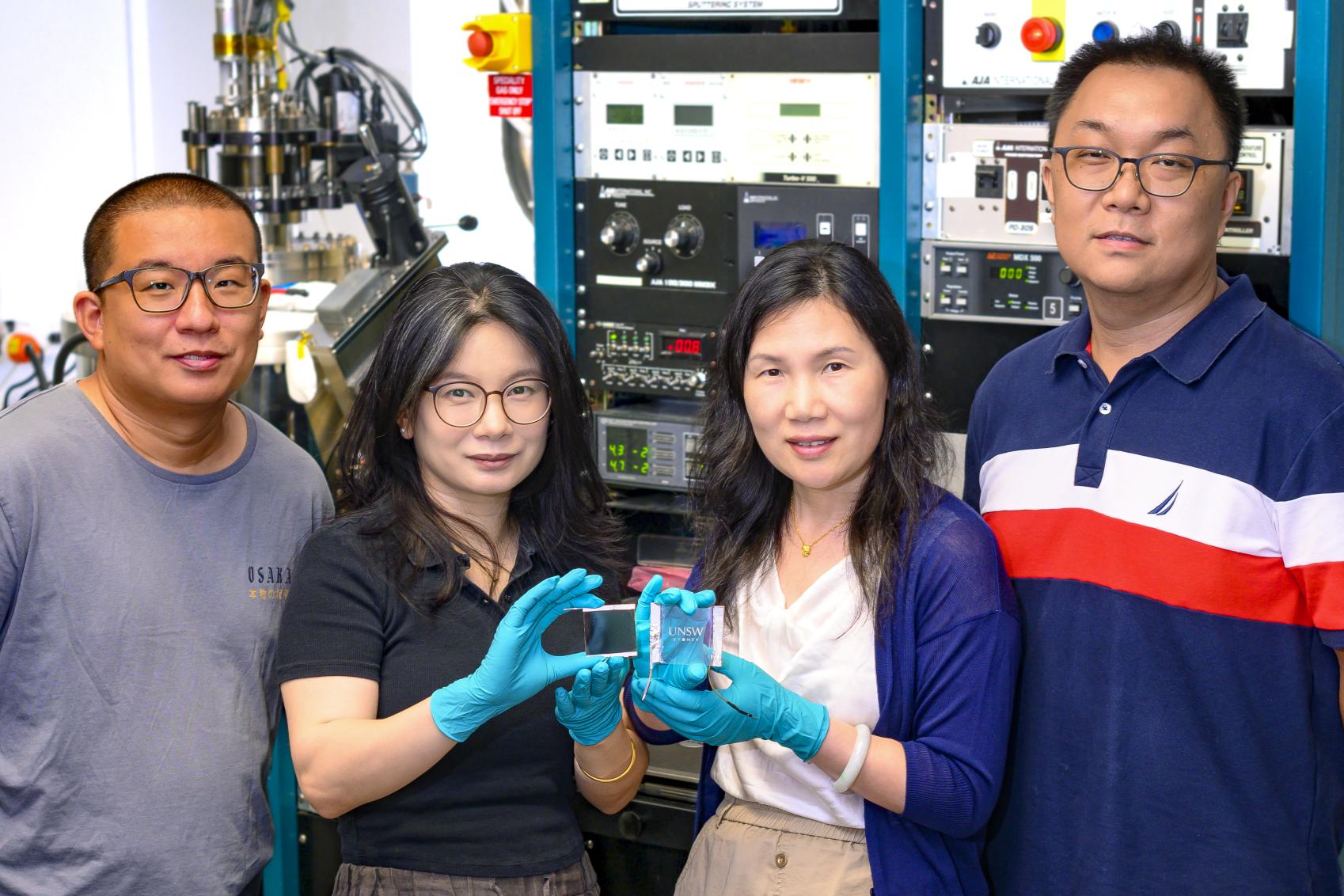

By pioneering both the practicality of a new polymer and its potential for mass-production, the UNSW team has shown a potential path forward allowing the integration of a variety of top cells with Si cells into a tandem one.

They developed a novel technology that can transform insulating polymers into conductive polymers. The method can maintain the good properties of insulating polymers, such as transparency and adhesivity, and equip the material with good conductivity, creating a new type of transparent conductive adhesive polymers.

This new polymer provides a low-cost and simple solution to integrate Si cells with top cells to fabricate tandem products.

Since this approach releases the constraints on sub cells, it's much simpler to upgrade the current Si and thin film cell fabrication capacity into next-generation tandem cell production as sub cells can be fabricated separately and then bonded together using this polymer.

It circumvents the challenging deposition process of directly growing thin film cells on textured Si surfaces and allows the use of commercial textured Si cell products directly from the industry.

The demonstration of the production process developed by this project has been promising with large Australian backers expressing interest in supporting the team’s commercialisation journey.

“We are happy with our progress so far and have set up a new company to continue our work,” Dr Liu said.

“Finalising our work through the Seed grant has been a great achievement, and we are now looking to build on our successes to secure further funding and advance development.”

AEA Seed grants support proof-of-concept projects to bridge the gap between research outcomes and commercialisation.