Case Study

Posted on

Solar energy, as a renewable and abundant resource, is pivotal to Australia’s commitment to achieving carbon net-zero emissions by 2050. However, current silicon solar panels, while reliable and scalable, face challenges in further improving power conversion efficiency and reducing production costs. These challenges present an opportunity for next-generation solar cells, such as perovskite solar cells (PSCs), to complement silicon technology and unlock new possibilities.

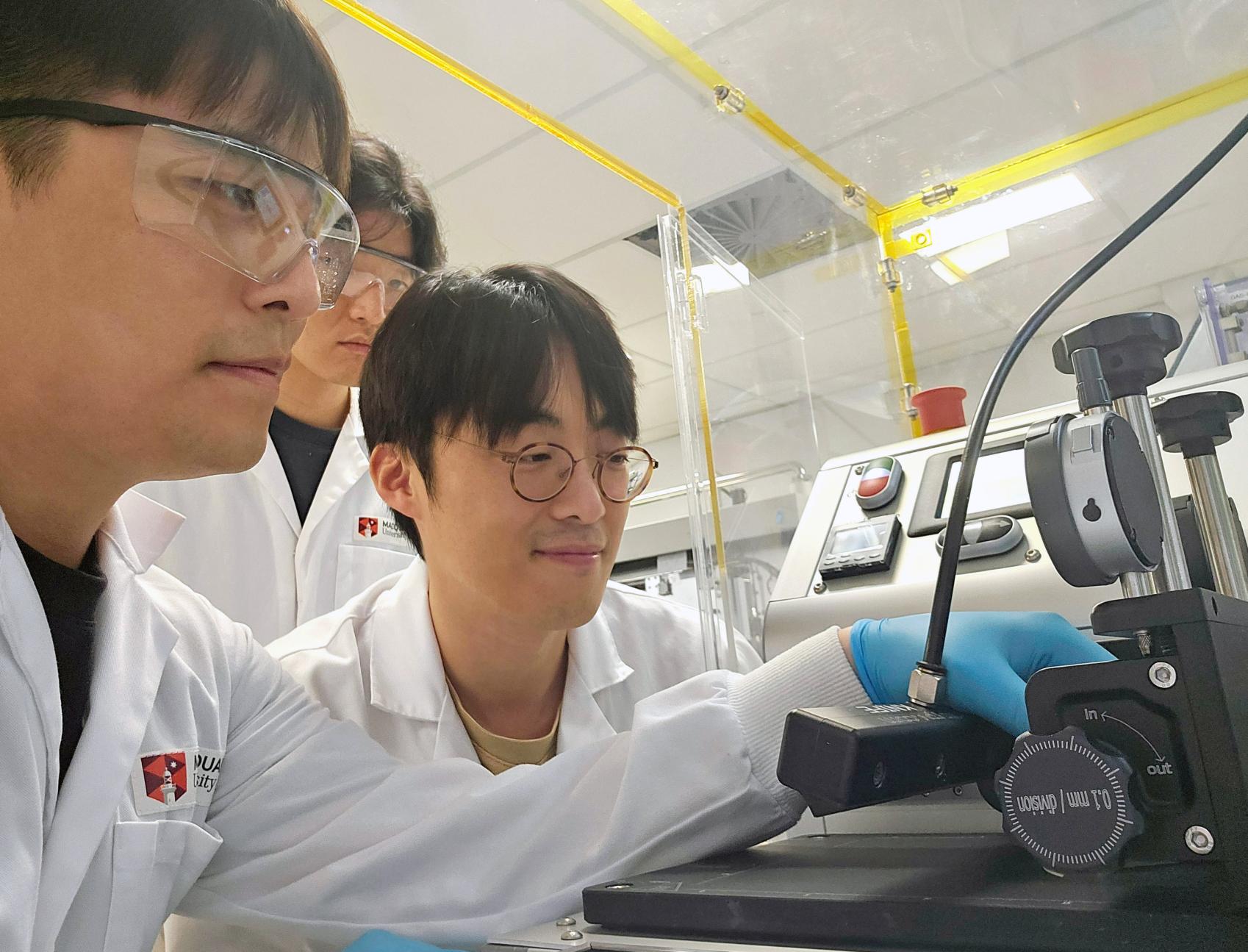

The Industrially viable manufacturing for next-generation solar cells project, led by Professor Shujuan Huang, Dr Jincheol Kim at Macquarie University in collaboration with Dr DJ Kim at UNSW, addressed key barriers preventing PSCs from achieving industrial adoption.

Toxic solvents used during fabrication pose significant risks to worker safety and the environment, restricting broader applications. Additionally, current electron transport materials (ETMs) are expensive and difficult to scale, and manufacturing processes require further optimisation to become commercially viable.

The project was supported by AEA Seed funding, which played a crucial role in achieving these significant breakthroughs. The funding facilitated the development of green, sustainable perovskite solar cell technologies, leading to high-impact publications, patents and strong industry partnerships.

The success of this work underscores the importance of continued investment in innovative research to drive commercial and environmental advancements.

To tackle the current industry issues, the researchers developed safe, eco-friendly solvents that can be used in large-scale manufacturing. These new solvents helped solar cells reach energy efficiencies of over 22%, making them safer for both the environment and workers.

Additionally, the team created affordable and scalable electron transport materials using graphene quantum dots (GQDs) made from natural fertilisers. These ETMs also achieved 22% efficiency and improved the stability of the solar cells.

‘With the support of AEA Seed funding, we successfully synthesised nitrogen-doped graphene quantum dots, which have greatly improved the efficiency and stability of our perovskite solar cells. This breakthrough has opened new avenues for commercial applications,’ Professor Huang says.

Another key development was an optimised method called slot-die coating, a way to apply materials evenly. This method resulted in solar cell modules with efficiencies of over 16%, which is one of the best performances globally.

Where to next

Professor Shujuan Huang and team are exploring other AEA grant programs, such as Ignite or Innovate, to provide additional investment.

‘Our project is strategically positioned to attract further investment by leveraging its key outcomes. The two potential patents stemming from this work—on green perovskite ink and slot-die coating for green PSC manufacturing—will be pivotal in securing industry partnerships and additional funding,’ Professor Huang says.

These programs could further support the development and commercialisation of perovskite solar cells, ensuring that the advancements made continue to contribute to Australia's carbon net-zero goals. Continued engagement with industry partners will be crucial in driving the project's future success.