Case Study

Posted on

Lifesaving surgery to repair a diseased or damaged heart valve can use either a mechanical replacement or a biological replacement made from cow, pig or human heart tissue.

Over time, these types of valve replacements will need to be monitored and potentially replaced multiple times leading to additional invasive surgeries, especially among younger patients.

Repeat surgeries and related medication impose not only a socioeconomic cost but also psychological and traumatic effects on both the patient and their family.

Supported by an Australia’s Economic Accelerator Seed grant, researchers at the University of Sydney are collaborating with industry partners to develop and commercialise a long-lasting and personalised solution to this problem.

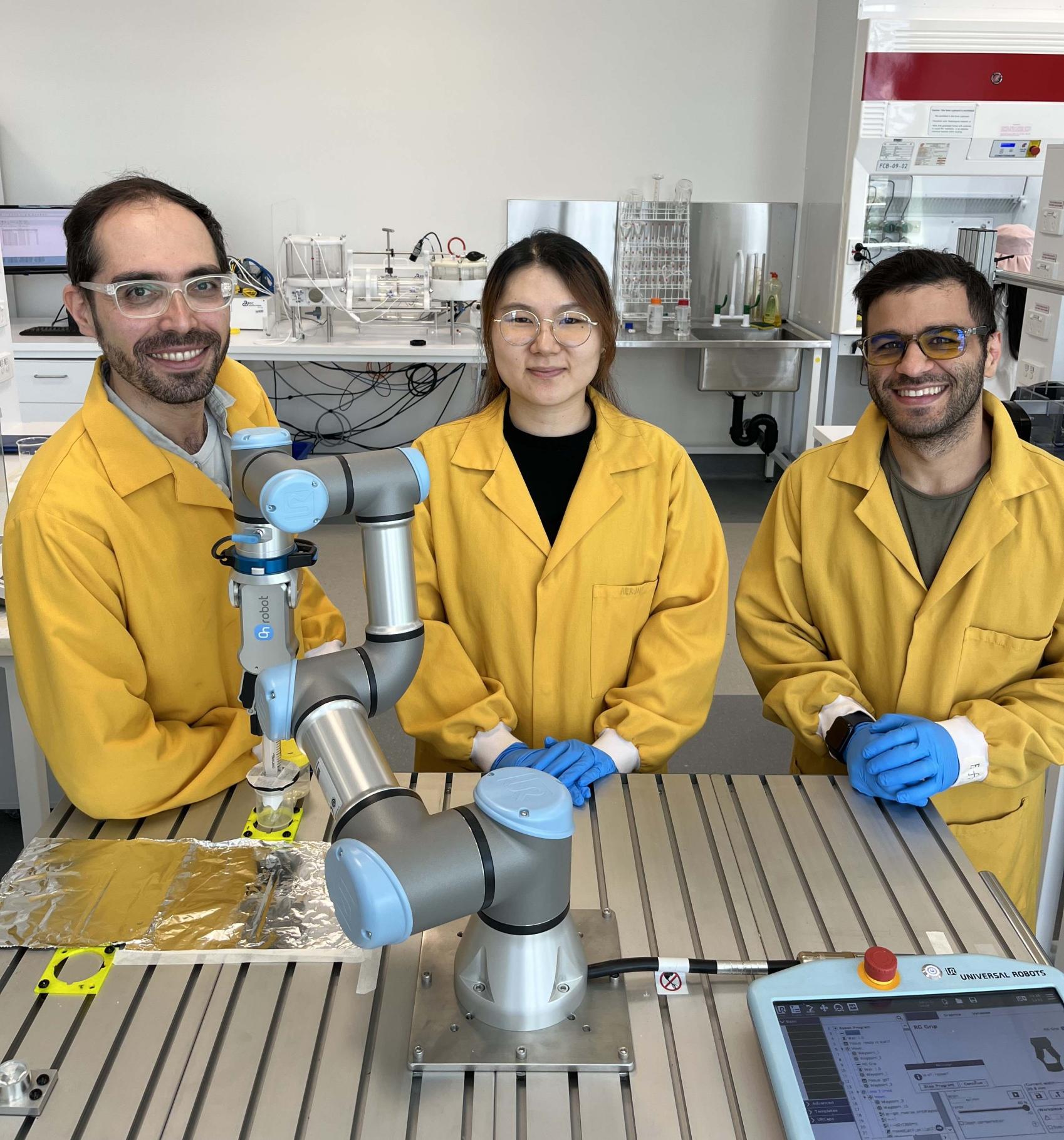

The polymeric heart valves utilise advanced robotics to target increased longevity and the potential for better customisation to an individual’s anatomy.

Sina Naficy, director and co-founder of start-up company LevTech, said the project brings together a broad range of expertise from their company, the University of Sydney and also the Lurie Children’s Hospital of Chicago.

“Our multidisciplinary team of clinicians, engineers, and researchers are working together towards creating a long-lasting solution that aims to reduce the number of operations a single heart valve disease patient will need to undergo from 4 (or more) to one,” Dr Naficy said.

“The future polymer-based valves will lead to significant impacts in the medical and health system as they will remove the need for numerous hospital visits and multiple invasive, high-risk procedures.

“The proposed technology can service the whole aortic and pulmonary valve replacement market segment. However, younger females and children will benefit the most because of freedom from anticoagulation and resistance towards highly active immune responses.”

Extensive wear testing of the polymeric valves will be conducted in early 2025 with a view to in vivo assessment taking place later in the year— animal studies in sheep will test the functionality and biocompatibility of the polymeric valves in the native environment.

Dr Naficy noted that industry collaboration was a cornerstone of the project allowing a focus on transformative research and technology that’s pragmatic rather than making something ‘cool or interesting’.

“No matter how amazing of an invention we create here at the university, in order to have a real-world impact, it is the commercialisation pathway that will see it realised,” Dr Naficy said.

“Our philosophy revolves around transformative research rather than an incremental change.”

AEA is a $1.6 billion Australian Government investment aimed at transforming Australia’s research translation and commercialisation landscape.

The program is funding projects that align with national priorities to help take innovative ideas through to proof-of-concept and proof-of-scale as projects progress towards commercialisation and the creation of new businesses.

Visit the AEA website and AEA LinkedIn page for further updates.